nasa 3d printed habitat challenge

about

NASA 3D Printed Habitat Centennial Challenge: Phase II Level 3

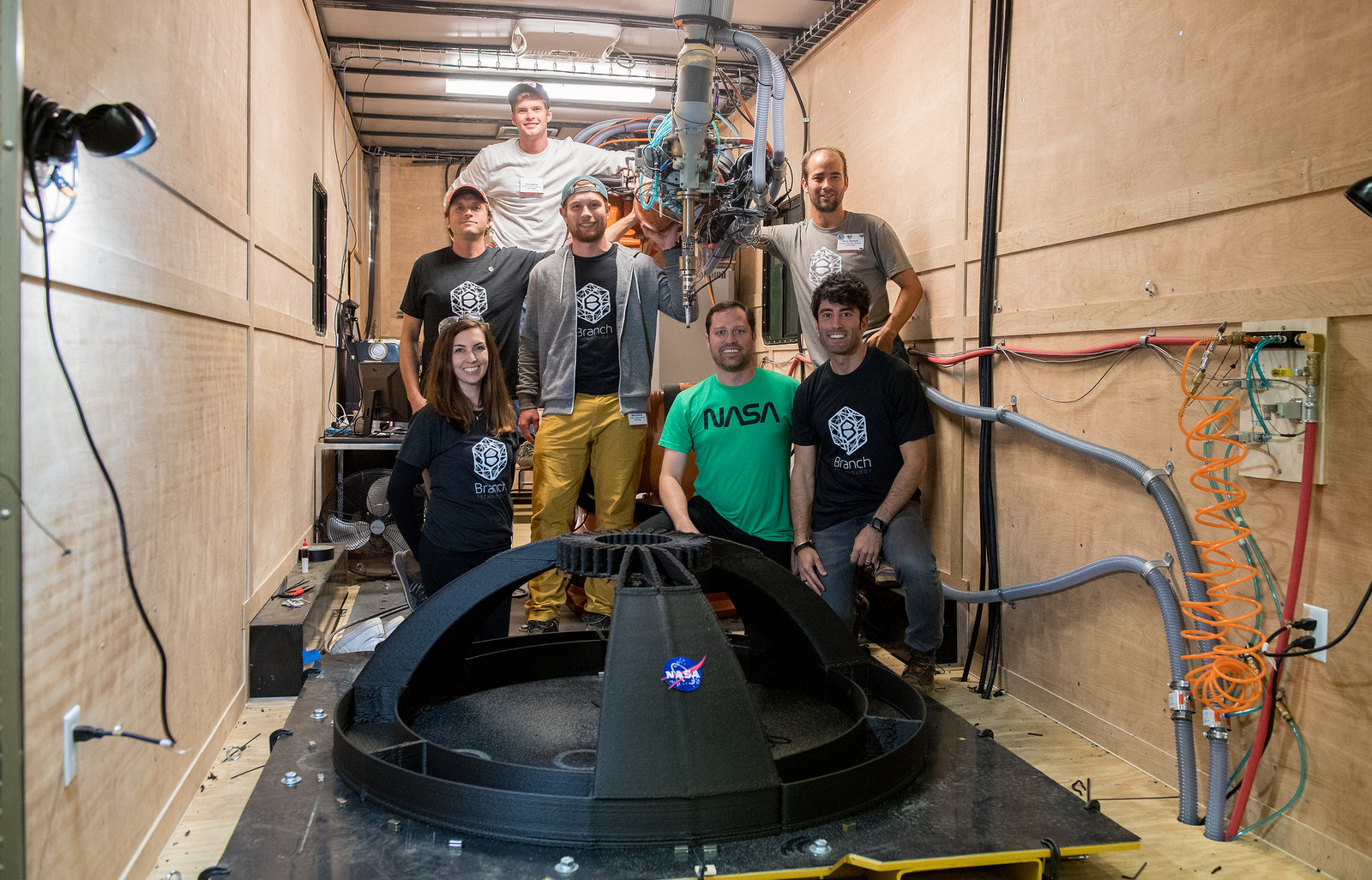

Partners: Foster+Partners Special Modeling Group, Techmer Polymer Modifiers

Date: August 2017

Roles: Materials Formulation & Testing, Specimens Prototyping, Hardware Development, Parametric Toolpath Design, Process Operation in On-Site Competition

As part of a larger effort to develop fundamental technologies to support deep space exploration, NASA’s Space Technology Mission Directorate established the Centennial Challenges program to incentivize companies and universities to explore the most promising technologies for the future of space.

The multi-phase 3D Printed Habitat Challenge focuses on developments essential to autonomously construct off-planet mission facilities prior to the arrival of human research crews. Where Phase I focused on habitat design, Phase II challenged participants to develop machines, materials, and methods to autonomously fabricate small-scale structural elements using materials that could be recycled from used spacecraft or harvested from off-planet environments.

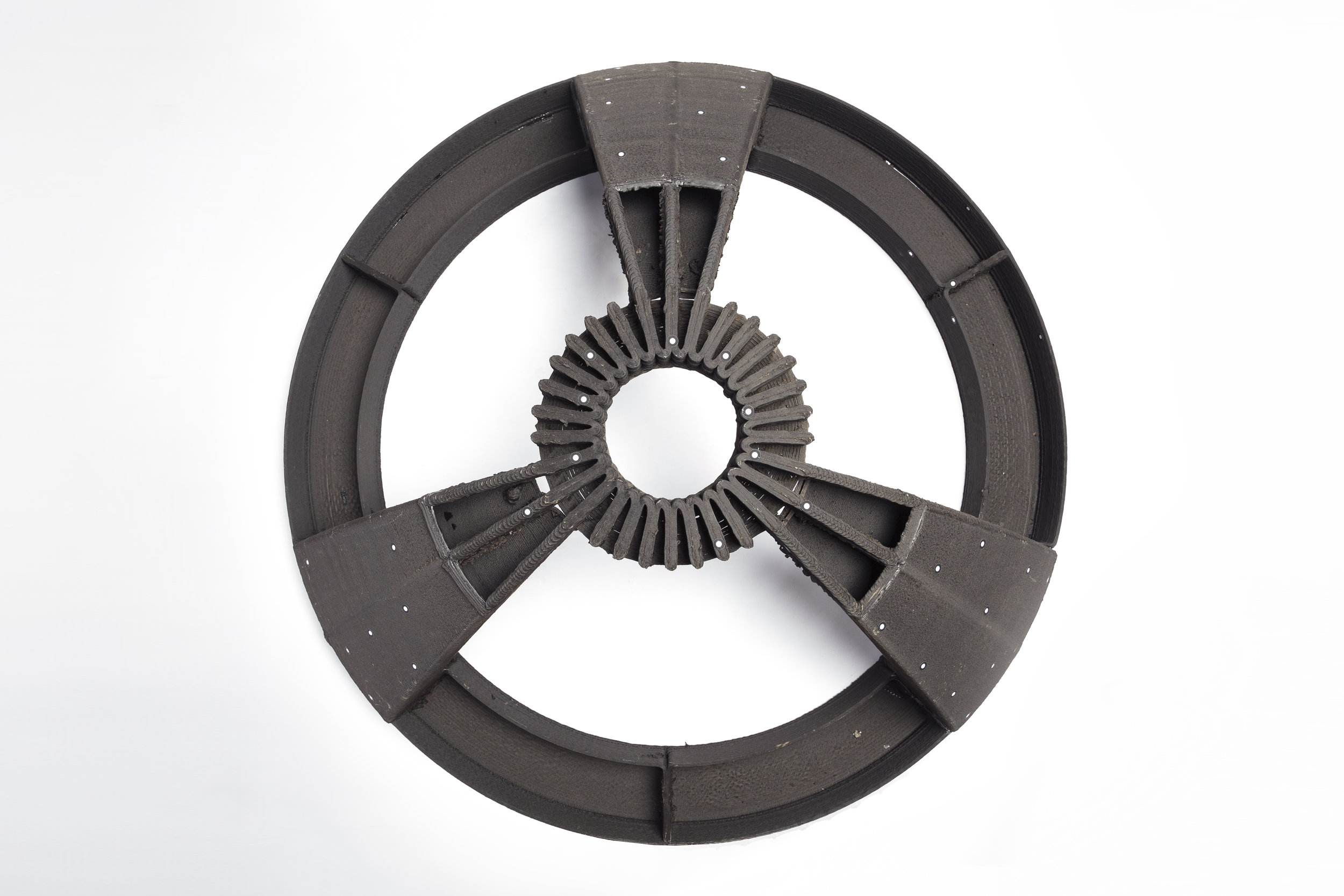

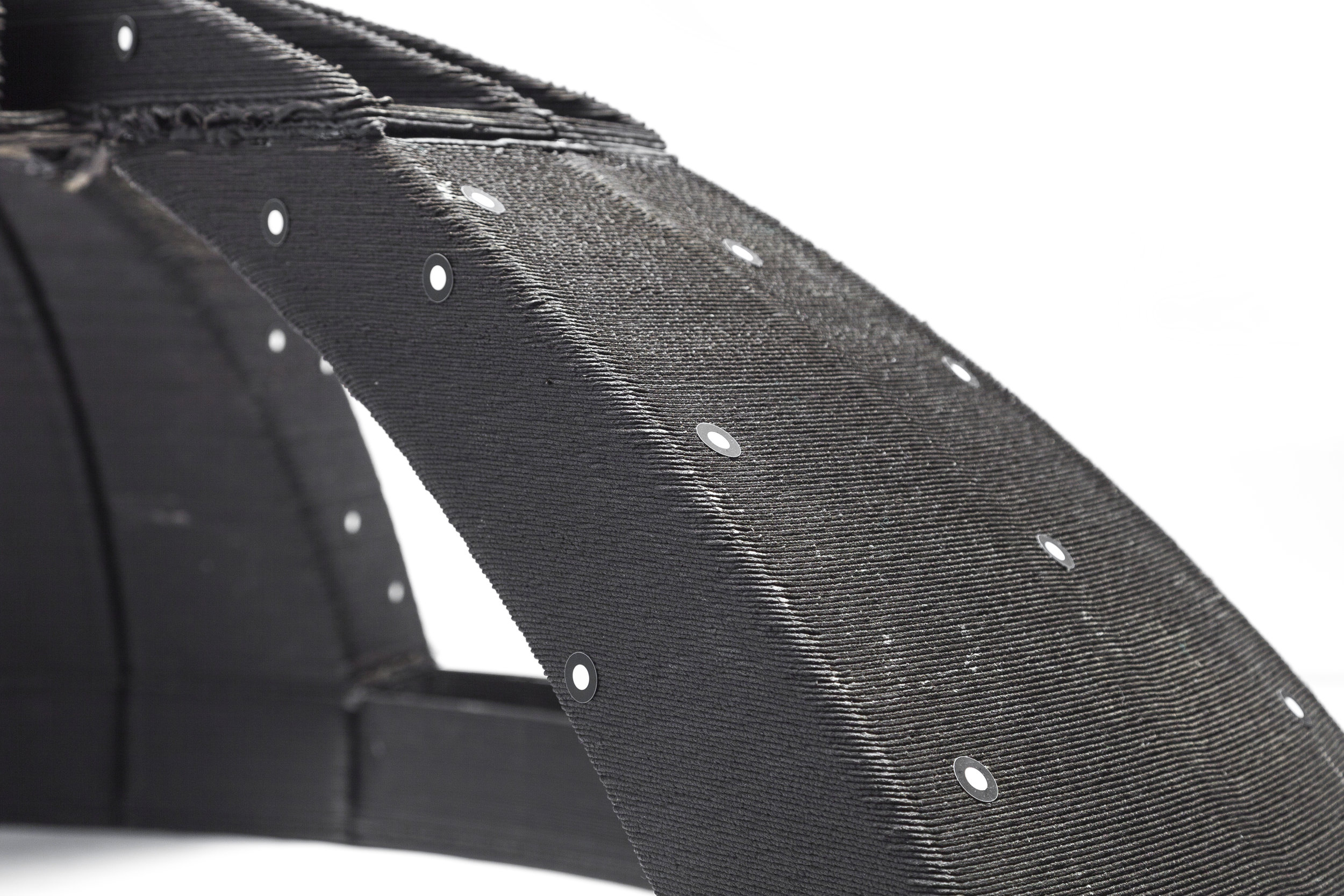

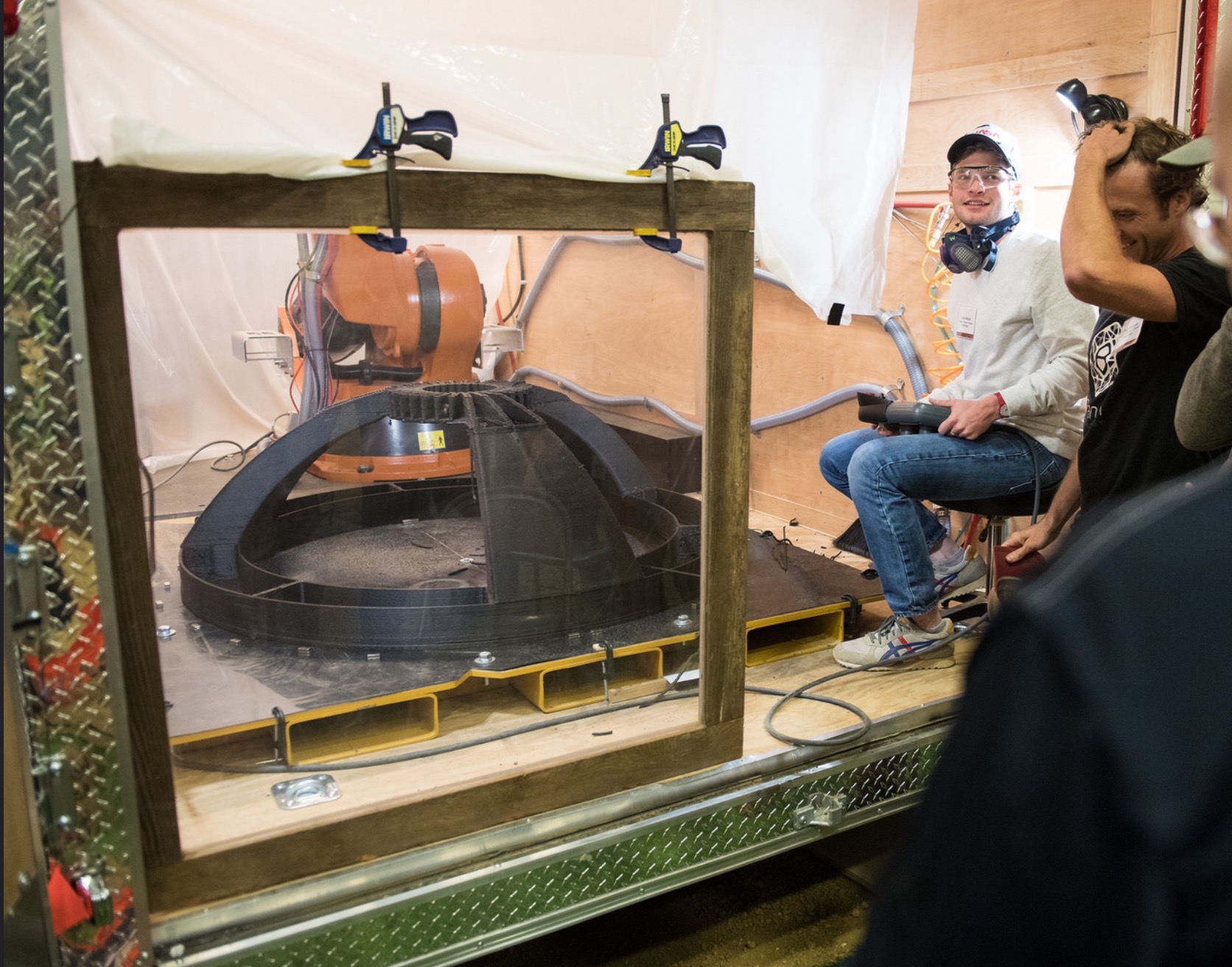

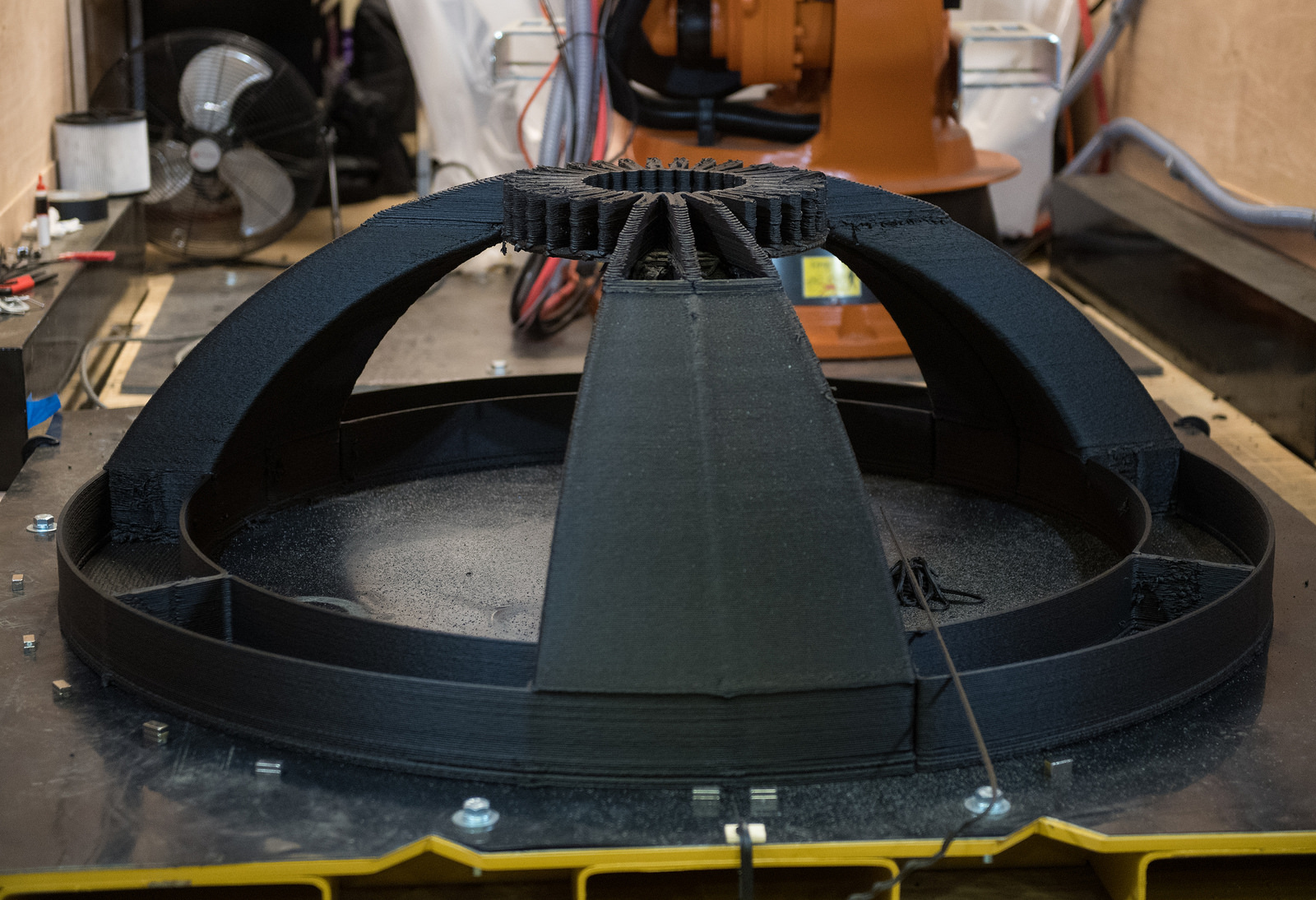

Branch and Foster worked with Techmer PM to formulate a 75/25% blend of Basalt Fiber and PETG, which fulfilled the competition’s indigenous and recyclable material requirements, respectively. The Branch team was responsible for developing autonomous printing hardware, and worked with Foster to fine-tune the specimen designs and fabrication strategies utilized in each level. Level 3 specimens included the cylinders and beams that were also created for Levels 1 & 2 respectively, as well as a dome structure 1.5m in diameter.

Among the greatest challenges the team encountered was the requirement to autonomously and fully remove any support material used to print the dome structure. To meet this requirement, the team leveraged its experience in freeform extrusion to eliminate the need for support entirely by creating a web structure that linked the structure’s arms together in midair. This represented a significant advantage over existing AM technologies.

The competition took place at Caterpillar’s headquarters in Peoria, IL, where judges from NASA, CAT, and Bradley University would observe the autonomous fabrication of cylinder, beam, and dome specimens within 2 limited time windows on separate days.

Of the 77 teams that registered to participate in Phase II, only 5 qualified for Level 3. Only Branch/Foster, Penn State, and South Korean startup MoonX managed to meet the strength and material composition requirements of Levels 1 & 2, as well as the hardware portability necessary to compete on-site in Level 3. Of these, only Branch/Foster and Penn State were able to fabricate the final specimens during the competition, the latter using concrete and removable forms.

The Branch/Foster team not only produced the specimens significantly faster, but achieved significantly greater strength properties. Most notably, the ~20kg Basalt/PETG dome held 1654kg compared to the 792kg held by Penn State’s ~100kg solid concrete version. Although strength:weight ratio was not a metric used in the competition, judges agreed that it would be a significant factor in real-world applications.

Hollow cylinder samples withstood compressive loads up to 28,100kg, while solid beam samples withstood flexural loads in excess of 15,800kg. Of particular interest to the judges and experts was the concrete-like fracture of the beams, which did not exhibit the anisotropic de-lamitation behavior typical of layer-based 3D printing.

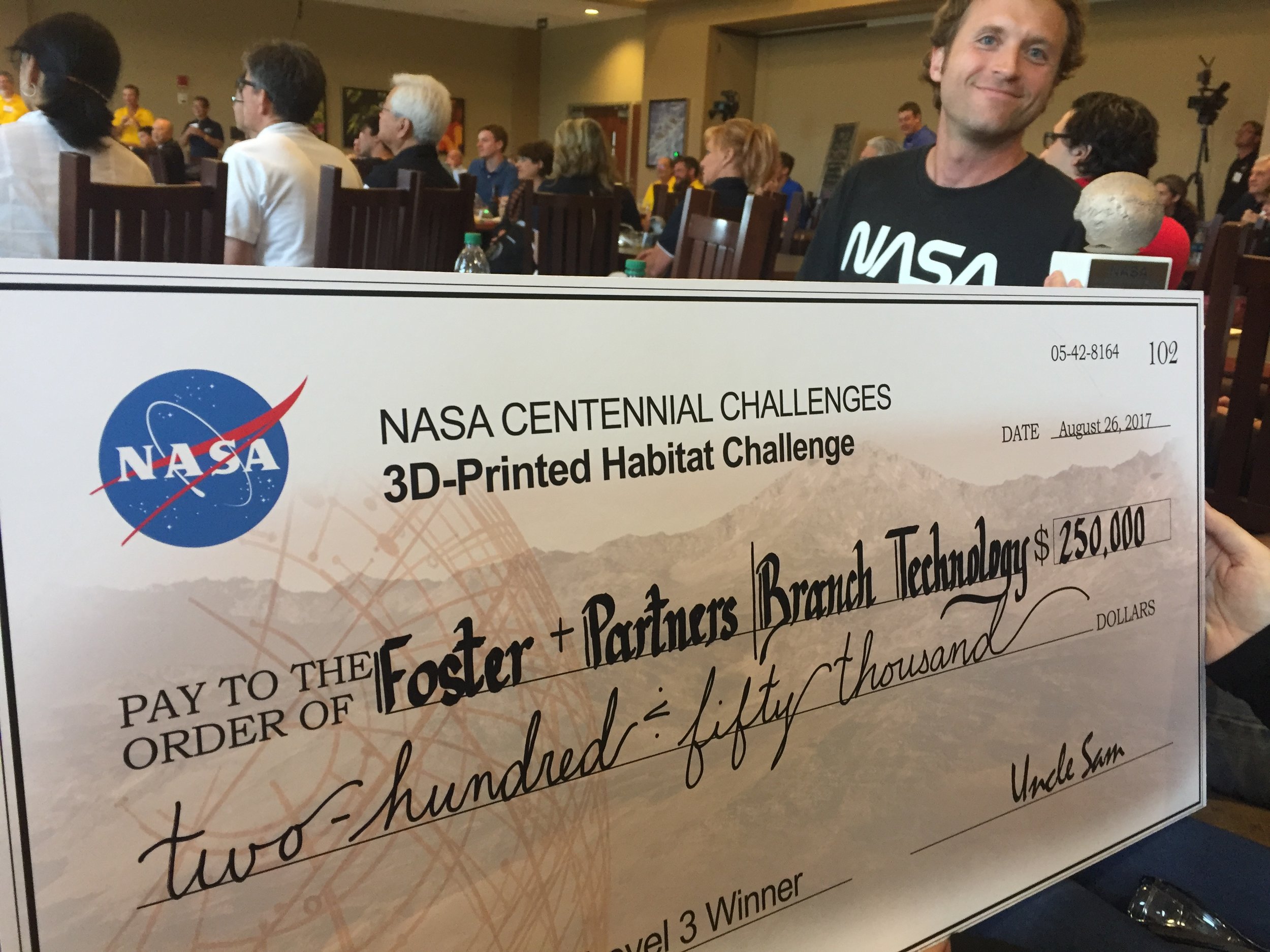

Branch and Foster were awarded $250,000 in prize money for 1st place in Level 3. Branch is continuing work with Techmer PM to license the Basalt/PETG material, now called “PolyRock” to NASA and other parties that have expressed interest following the competition.

Photo Credits: Foster + Partners, Branch Technology

Video Credit: The New York Times, Squared Away Films

More:

https://www.branch.technology/projects-1/2017/6/9/nasa-3d-printed-habitat-challenge