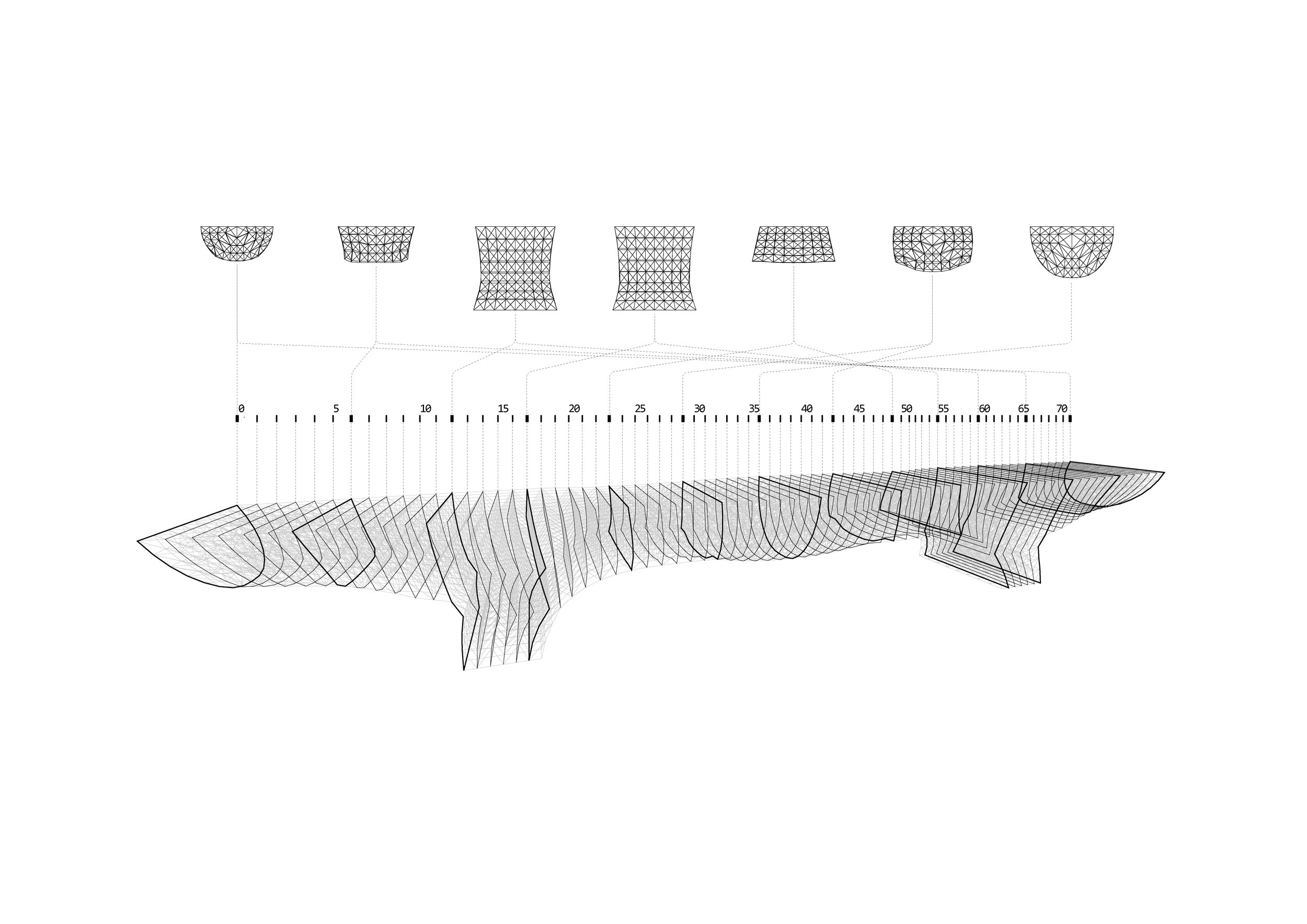

Optimized Composite

about

Design: Caitlin Muller, Mark Tam, MIT Digital Structures

Date: January, 2017

Roles: Process Constraints Characterization, Materials, Fabrication, Milling, Composite Layup

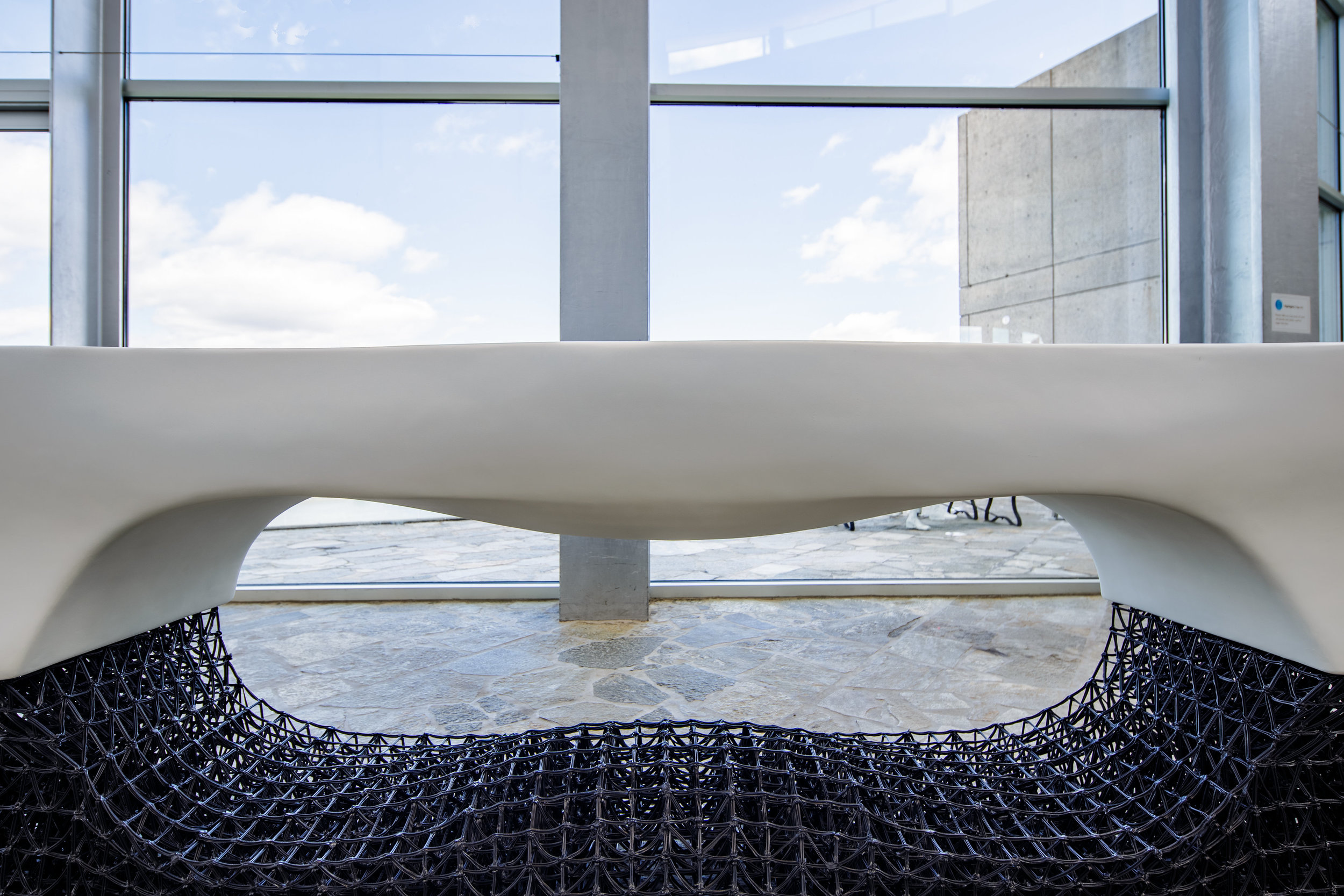

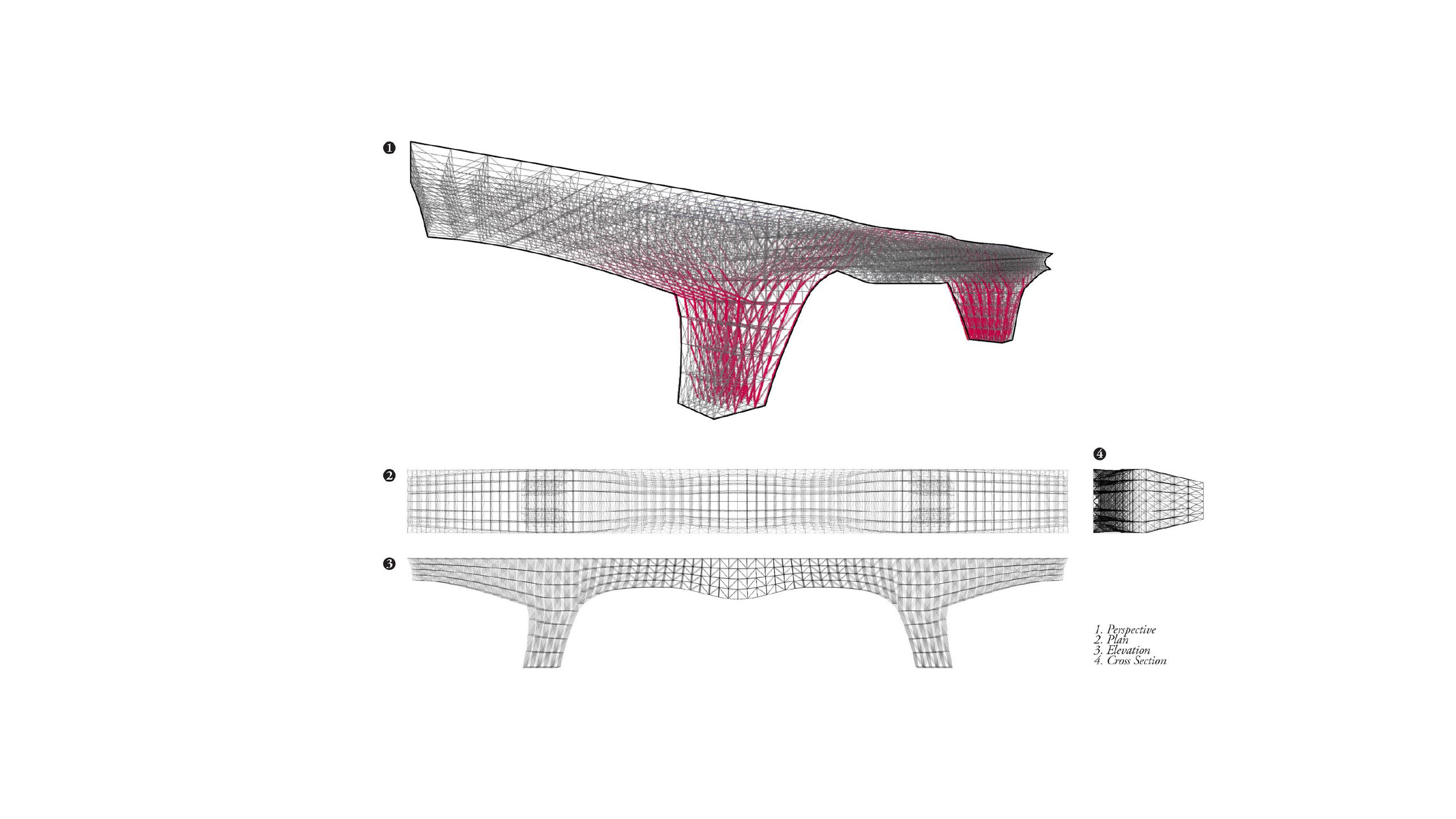

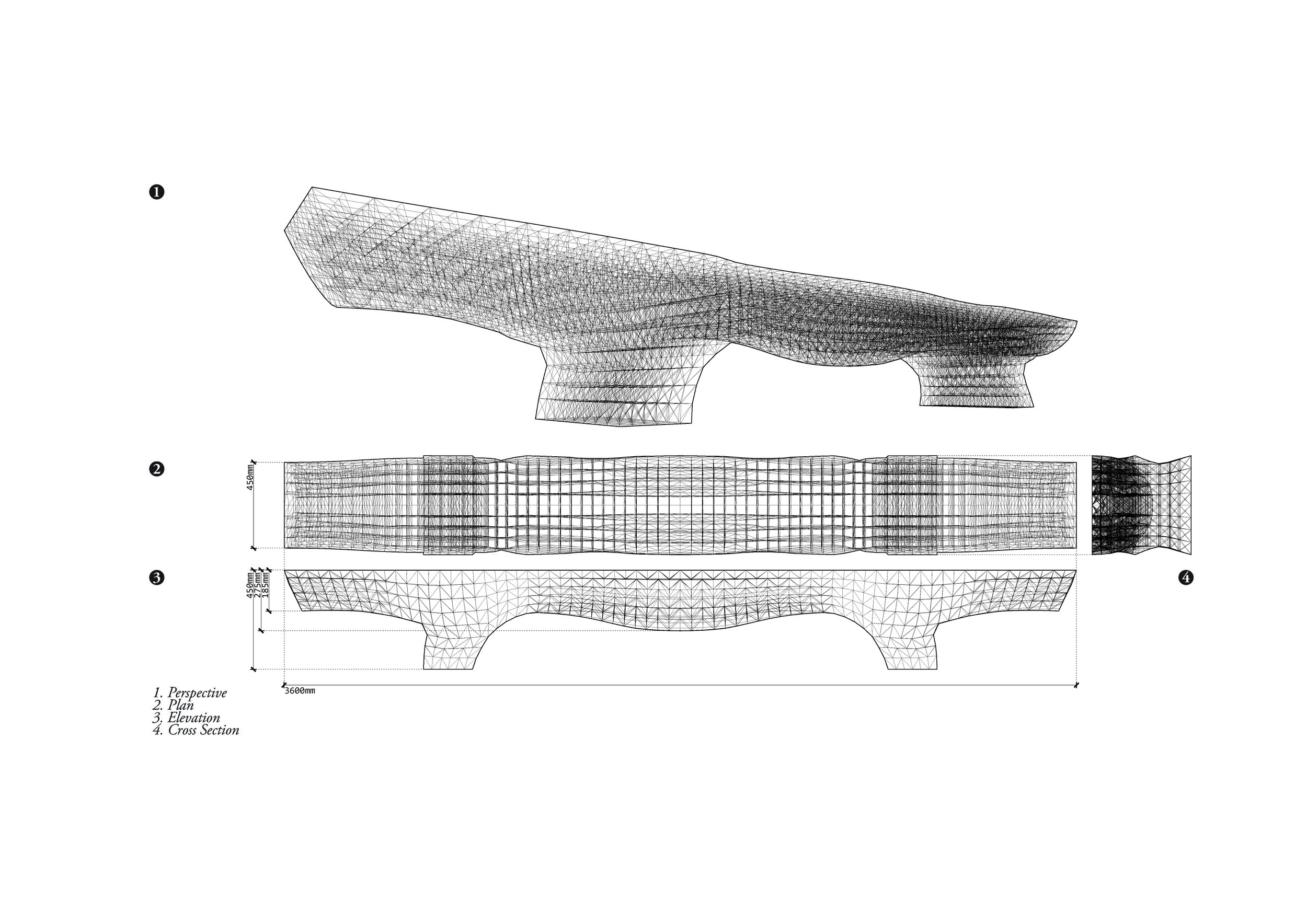

The Branch team collaborated with MIT Digital Structures to leverage spatial 3d printing technology with MIT’s research in topology optimization and Stress Line Additive Manufacturing. The teams designed and fabricated two optimized beams, one of which was filled with polyurethane foam, robotically milled, and finished with fiberglass to form a complete composite. The project was intended to demonstrate how Branch’s Cellular Matrix structures could effectively utilize computationally optimized forms to create robust yet lightweight composite structures.

Image Credits: Branch Technology, Digital Structures

More:

https://www.branch.technology/projects-1/2017/6/9/03ql2cdrn68r86l3whatjw5ucl9dlu