Note: I am still in the process of building this page - please excuse any template content, etc. that may appear on the site from time to time.

What is Cfab™?

CFAB™ is a digitally-driven composites manufacturing process for the architecture, engineering, and construction (AEC) industry. CFAB™ integrates a variety of technologies to create robust bespoke building elements. It is the first building technology to leverage 6D printing to realize the geometric complexities of contemporary building design.

Developing CFAB™

Computational Geometry

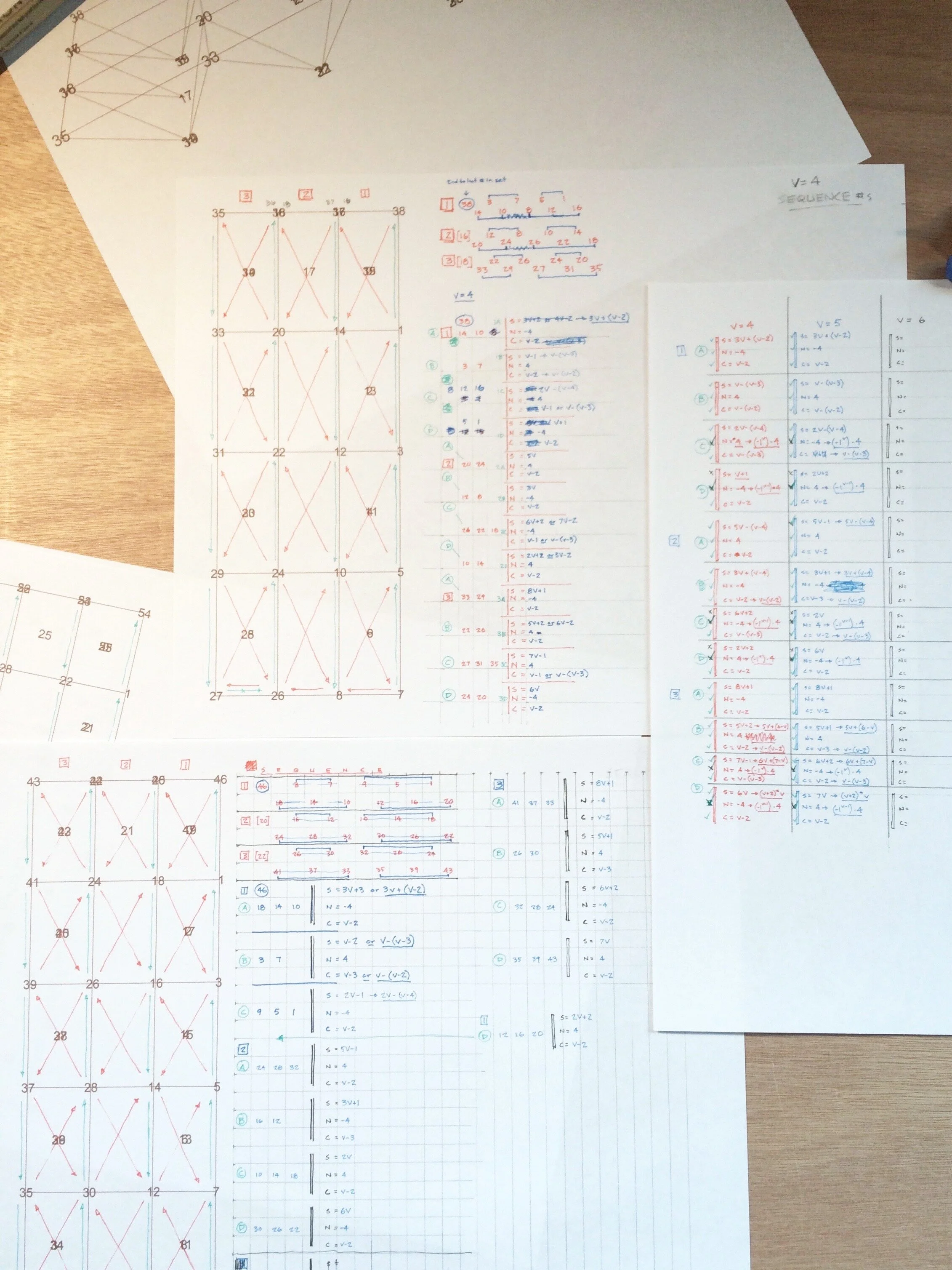

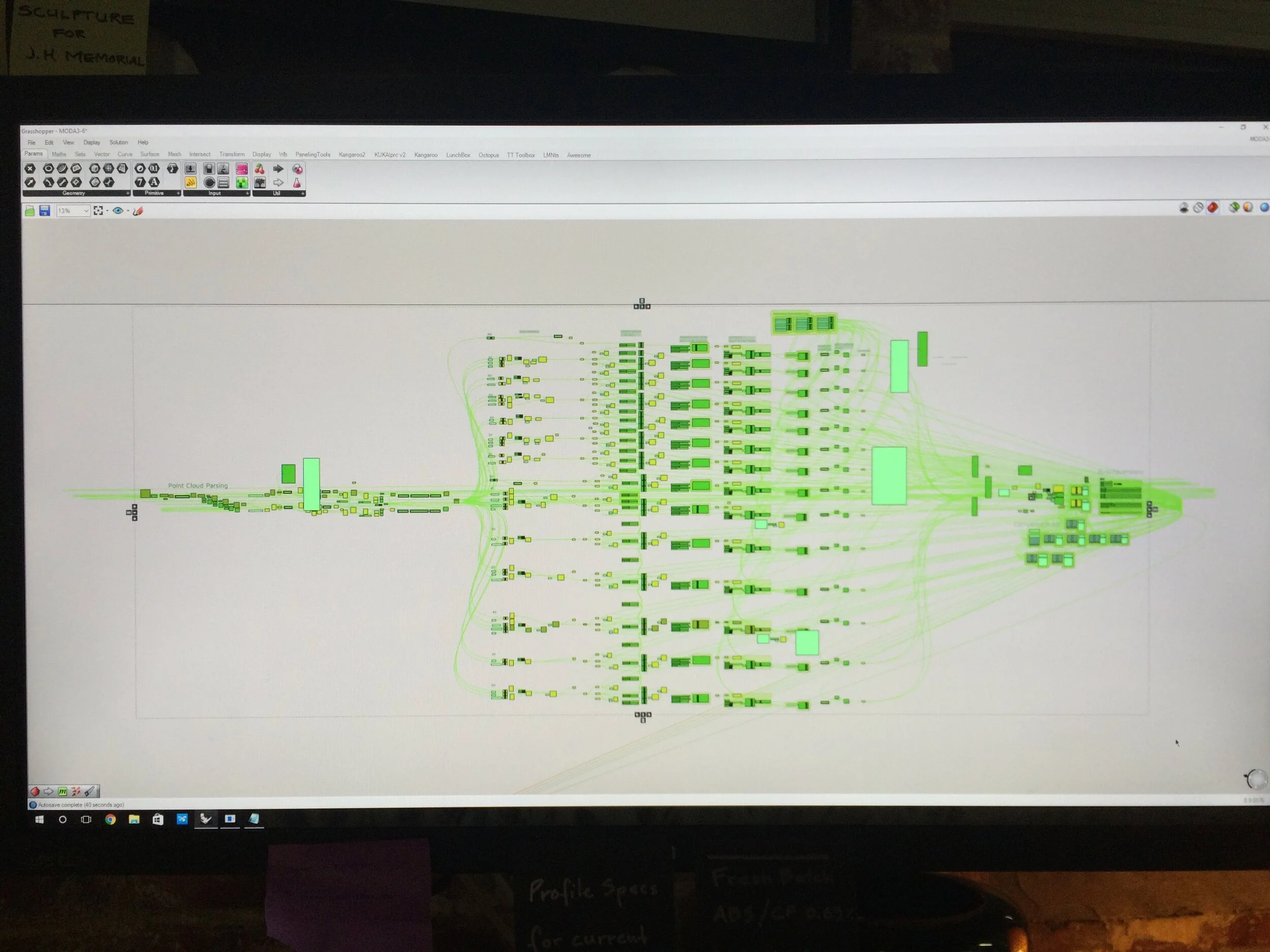

One of my first projects at Branch Technology was the development of software algorithms to create, sequence, and export the print geometry and programming for our spatial extrusion process.

First, a 3D model provided by the client is broken into individual parts or panels that will make up the final construction assembly. These parts are then mapped with a 3D wireframe structure. The edge dimensions and relative angles within this structure are based on the constraints of the physical printing process.

The wireframe serves as the basis for generating a 3D toolpath along which the printer will move during production. Many thousands of individual movements are linked together in a sequence that minimizes starts/stops that slow down production.

Each movement is assigned dozens of parameters that control the 6D orientation, speed, and extrusion of the printhead as it moves along the toolpaths. This sequence of complex movements and I/O commands is then exported as a program for the 7-axis industrial robots that serve as our production printers.

Originally written entirely in Grasshopper, this pre-production workflow has evolved through hundreds of iterations, and now integrates a variety of programming and modeling tools that make up the ‘digital production’ process.

spatial extrusion

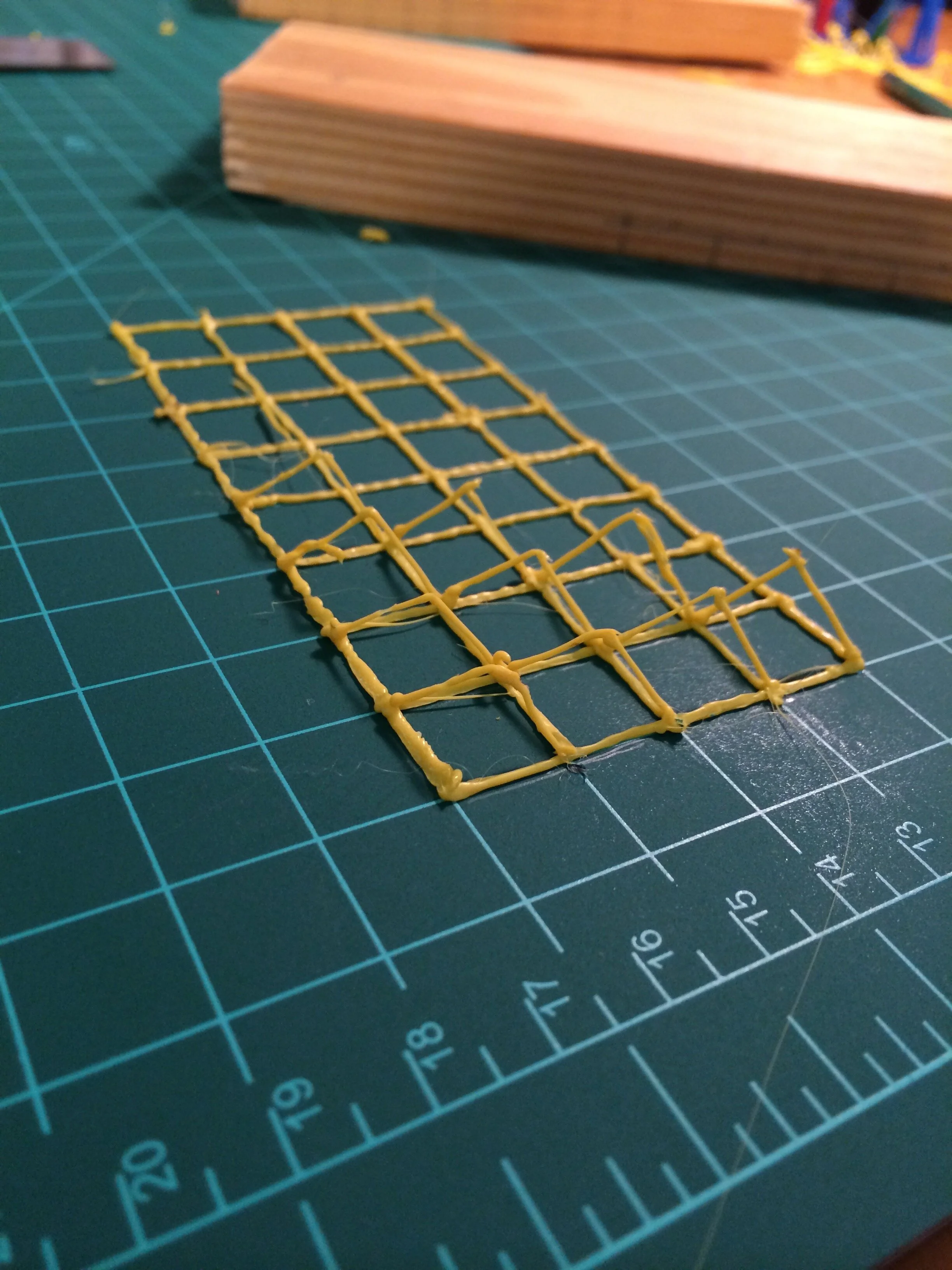

At the core of CFAB™ is a unique spatial extrusion process that produces the structural matrices used in composite parts.

Though it may seem simple, plastic extrusion is an extraordinarily complex process at industrial scale. I worked countless hours with my colleagues over several years to develop the hardware, process parameter controls, and even the plastics themselves in order to achieve the consistency and automation needed for commercial viability.

integrated materials

While the extruded polymer structure has aesthetic applications by itself, our intended commercial applications involve integrating other building materials to form bespoke composite components. CFAB™ is a tool that lets us use conventional building materials more freely and efficiently. In order to build geometrically complex components, the industry today utilizes casting and moulding techniques that require an enormous amount of labor and material to produce.

This presents designers with a “pick two” problem. An ideal construction process is Sustainable, Affordable, and Flexible enough to achieve a wide variety of design goals. In reality, you can rarely achieve any two of these qualities without compromising the third.

CFAB™ creates almost zero waste (sustainable), uses inexpensive and proven materials (affordable), and is entirely bespoke (flexible). Our system enables clients to build designs that would cost upwards of $1000 per square foot at a price point typical of commercial construction (under $200/sq. ft.). With CFAB™, there is no “pick two” problem.